High pressure reactors for the process industry

3D-Printing in plant and equipment

Potential of additive manufacturing for process engineering at THALETEC

THALETEC GMBH

THALETEC is the company with the world‘s greatest experience and the longest tradition in processing the glass-steel compound material. The first developments in glass lining technology started as early as 170 years ago. Today, our more than 190 employees produce apparatus and products coated with technical glass for the chemical and pharmaceutical industry.

The company places great importance to quality. All of our products are „Made in Germany“. This has been certified, and documented to DIN ISO 9001 and proven on a regular basis. The vast majority of our materials and external parts also are of German origin, enabling us to most efficiently fulfill our high claim to quality and reliability of our products.

New solutions for the process industry

Additive Manufacturing and especially 3D printing are regarded as „game changer“ for many industries. How big is the potential really for the apparatus and plant in the process industry and what challenges lie ahead will be shown by the example of a newly developed high-pressure reactor of THALETEC.

High pressure reactors are used in process engineering for carrying out chemical reactions under pressures up to 200 bar. So far, these reactors are machined manufactured from materials such as stainless steel or Hastelloy. For use in chemically highly aggressive products high pressure reactors are also equipped with a liner made of PTFE.

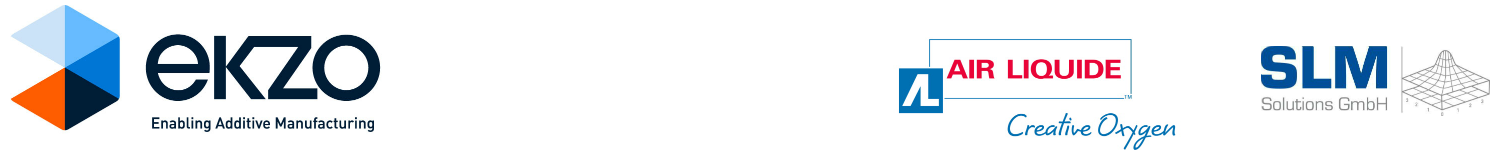

THALETEC has developed for this application, the prototype of a glass-lined high-pressure reactor (Figure 1). This new solution was prepared using the additive, metal-based manufacturing process, the „Selective Laser Melting“ (SLM®). The use of this manufacturing process opens the way to carry out the high-pressure reactor with an integrated temperature control channel for the heating or cooling of the reactor interior.

The combination of enamel and integrated temperature control channel provides over previously available solutions significantly improved heat transfer between the product and temperature control and thus the opportunity to influence the heat effect of the process better. Moreover, a higher pressure holding ability is possible despite lower wall thicknesses and achieved a guaranteed non-diffusive and chemically highly resistant coating in the wetted interior. Further, the weight of the high-pressure reactor is reduced, which is in the handling of the reactors in the laboratory of importance.

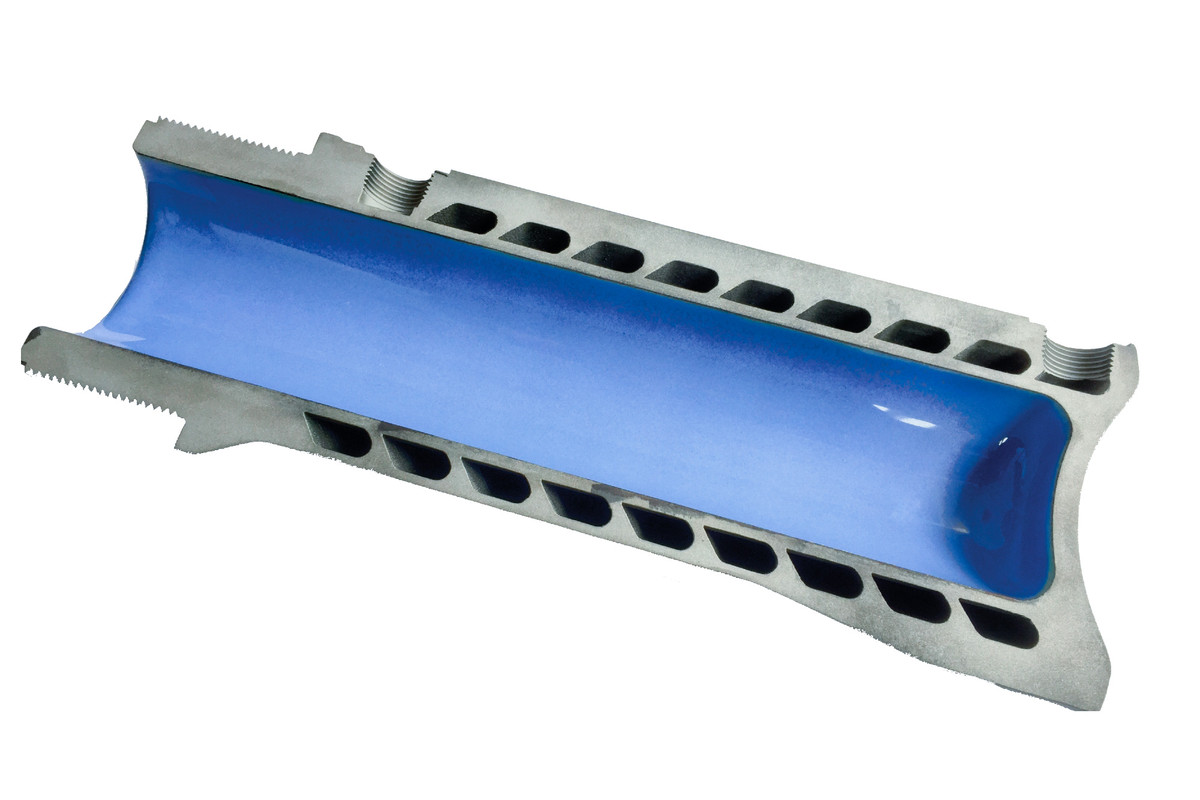

By the SLM® method it is possible to produce inner structures such as ducts and voids in complex components which cannot be produced by conventional machining manufacturing processes such as turning, milling and drilling. When using the SLM® process the component is developed in the 3D CAD system and geometrically optimized, first the component will be processed digitally and then supplied to the SLM® system (Figure 2). Therein the component is built up in layers. The metal powder used by THALETEC for Selective Laser Melting can be glass-lined.

In order to use high-pressure reactors, they must according to Pressure Equipment Directive 97/23 (PED) and must be designed and executed for a valid set of rules, for example AD 2000. In close cooperation with a notified body additively manufactured high-pressure reactors of THALETEC can be produced according to the approved pressure equipment. THALETEC has a tested and proven approach that makes it possible to certify pressure equipment additively manufactured according to PED.

The prototype of additively manufactured high-pressure reactor was developed in close cooperation with the company THALETEC GmbH and the engineering office JUREC (www.jurec.de). The engineering office JUREC specializes in supporting small and medium enterprises, exploit the potential of additive manufacturing. JUREC advises these companies in the development and design of additive manufactured components in mechanical engineering and chemical engineering.

High pressure reactors for the process industry

- Glass-lined high pressure reactor with temperature control channel additively manufactured in one piece in the SLM® process - Increased pressure holding capacity despite lower wall thicknesses - Weight savings for better handling of the reactors in the laboratory - Advantages in the process through the combination of glass-lining and integrated temperature control channel - Holistic advice and support along the SLM® process through cooperation with JUREC